Revers gear, weight approx. 300g.

Revers gear, weight approx. 300g.Friday, March 30, 2007

Thursday, March 29, 2007

The stuff from england finally arrived, putting shocks on, 2nd version of race numbers

Sunday, March 25, 2007

Side panels, race numbers, fitting the engine cover, exhaust, installing the propshaft

It's 25th March, and the car should be ready before 5th April for a car show. Starting to feel the pressure...

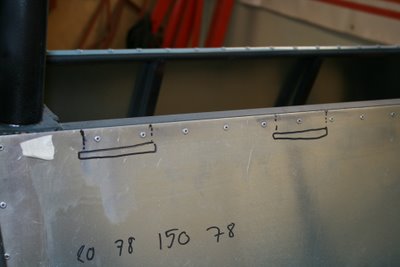

Testing how the side panels fit. We decided to make them the easiest way, just a plain sheet of aluminium with a couple folds. Thanks to Reiska for making them!

Testing how the side panels fit. We decided to make them the easiest way, just a plain sheet of aluminium with a couple folds. Thanks to Reiska for making them!

Fitting the engine cover. We had to make a hole to fit the carburetors.

Fitting the engine cover. We had to make a hole to fit the carburetors.

The carburetors stick out a bit. According to the rules no mechanical parts can stick out, so we will have to make a small addition to the engine cover to raise it over them. The air filter is allowed to stick out.

The carburetors stick out a bit. According to the rules no mechanical parts can stick out, so we will have to make a small addition to the engine cover to raise it over them. The air filter is allowed to stick out.

First version of the racenumbers. In our class the racenumbers come from the chassis number, this is the 19th Locost in Finland to get chassis numbering.

Testing how the side panels fit. We decided to make them the easiest way, just a plain sheet of aluminium with a couple folds. Thanks to Reiska for making them!

Testing how the side panels fit. We decided to make them the easiest way, just a plain sheet of aluminium with a couple folds. Thanks to Reiska for making them!

Fitting the engine cover. We had to make a hole to fit the carburetors.

Fitting the engine cover. We had to make a hole to fit the carburetors. The carburetors stick out a bit. According to the rules no mechanical parts can stick out, so we will have to make a small addition to the engine cover to raise it over them. The air filter is allowed to stick out.

The carburetors stick out a bit. According to the rules no mechanical parts can stick out, so we will have to make a small addition to the engine cover to raise it over them. The air filter is allowed to stick out.Sunday, March 18, 2007

Final adjustment of the engine mounts, making the engine cover and fitting the rear discs

Final adjustment of the engine mounts. Just making sure that the engine is easy to install and remove.

Final adjustment of the engine mounts. Just making sure that the engine is easy to install and remove. "Gelcoated" seat mold. No one told me that gelcoat needs hardener...

"Gelcoated" seat mold. No one told me that gelcoat needs hardener... Making the model for the engine cover.

Making the model for the engine cover. The cardboard model.

The cardboard model. The cardboard model ready to be cut. The lines were drawn on the inside.

The cardboard model ready to be cut. The lines were drawn on the inside. Bending the engine cover wasn't an easy task. It took three men and a lot of force to get it into shape. Atleast it's stiff.

Bending the engine cover wasn't an easy task. It took three men and a lot of force to get it into shape. Atleast it's stiff. Fitting the Lada front disc to the rear axle. The diameter of the mounting flange had to be reduced a bit to make it fit.

Fitting the Lada front disc to the rear axle. The diameter of the mounting flange had to be reduced a bit to make it fit.

Saturday, March 3, 2007

Measuring the center of gravity

This thursday the car felt complete enough to measure where the center of gravity is so we could reduce the guesswork when ordering springs. There's still some components missing, so we replaced them with additional weight. Measuring without the wheels on is probably more accurate than with them because now there isn't a flexible tire that messes with the results, and you don't have to lock the suspension. The weight and location of each suspension was compensated in the calculations. We will do the same measurements when the car is ready. Then also probaby without suspension.

The wrench is instead of the upper waterhose.

The wrench is instead of the upper waterhose.

The lead weight instead of the fuel tank and exhaust.

The lead weight instead of the fuel tank and exhaust.

The car ready for measurement.

The car ready for measurement.

The mandatory "without hands" shot. This was the easier side because the driver wasn't as heavy when lifting the car, so we could afford having one of us taking photos. It's the second measurement and you can see the drivers neck getting tired.

Those who have a roll angle gauge in their car might be interested to know that without tires it will tip over at 60 degrees.

Big thanks to Kalevi, without his help we wouldn't have dared to lift the frame.

The wrench is instead of the upper waterhose.

The wrench is instead of the upper waterhose. The lead weight instead of the fuel tank and exhaust.

The lead weight instead of the fuel tank and exhaust. The car ready for measurement.

The car ready for measurement.

The mandatory "without hands" shot. This was the easier side because the driver wasn't as heavy when lifting the car, so we could afford having one of us taking photos. It's the second measurement and you can see the drivers neck getting tired.

Those who have a roll angle gauge in their car might be interested to know that without tires it will tip over at 60 degrees.

Big thanks to Kalevi, without his help we wouldn't have dared to lift the frame.

Sunday, February 18, 2007

February's progress

Places for the shoulder harnesses. According to FIA regulations they have to last a force of 14700N per belt. According to calculations just the tube should be enough. This solution was much more lighter than adding a roll cage tube into the trunk area to mount the tubes.

Places for the shoulder harnesses. According to FIA regulations they have to last a force of 14700N per belt. According to calculations just the tube should be enough. This solution was much more lighter than adding a roll cage tube into the trunk area to mount the tubes. We started to install the engine electrics. The wiring is sorted out and all the components are installed.

We started to install the engine electrics. The wiring is sorted out and all the components are installed. We decided to add a tube to give protection for the driver's feet. There will also be a diagonal brace in the "roof". The steering axle is mounted, main electrical cut off switch is installed and the fenders have been installed.

We decided to add a tube to give protection for the driver's feet. There will also be a diagonal brace in the "roof". The steering axle is mounted, main electrical cut off switch is installed and the fenders have been installed. A closer shot of the rear fender mounting. There's also screws on the inside.

A closer shot of the rear fender mounting. There's also screws on the inside. At this point there's so much to design as we build the first car, that when we get resistance or are waiting on parts to arrive it's nice to go to the other car and do the same stuff that we already did on the first.

At this point there's so much to design as we build the first car, that when we get resistance or are waiting on parts to arrive it's nice to go to the other car and do the same stuff that we already did on the first. Gearshifter placement. It will be on the right side, next to the roll bar.

Gearshifter placement. It will be on the right side, next to the roll bar. The gearshift cable at the engine end.

The gearshift cable at the engine end.(EDIT 2008: This shifter as we installed it isn't advised. The cable made such tight bend that it had enormous friction. It was a bit tricky to shift because the lever didn't move back to the middle position by itself. Also finding neutral was difficult)

Wednesday, February 14, 2007

FEA, frame with roll cage and panels installed

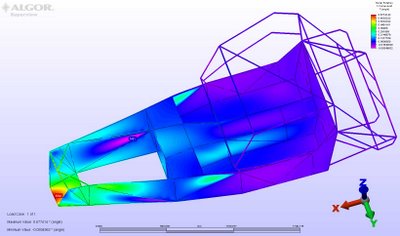

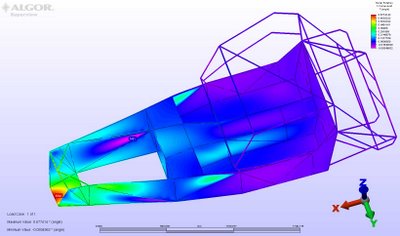

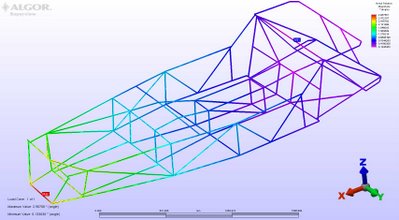

I finally got all panels attached, and the stiffness raised quite dramatically.

The colors show how much the frame twists, red being the highest. Same forces as in the previous pictures.

The colors show how much the frame twists, red being the highest. Same forces as in the previous pictures.

The torsional stiffness is 4165Nm/deg, which is quite much more than the numbers by Ron Champion (1630-2030Nm/deg). The roll cage brings more stiffness, and the stiffness of the ready frame is usually 15-20% less than that of the calculated.

The frame is as it will be when we build the car, so all wall thicknesses for the tubes are 1,5mm. The floor, firewall and propshaft tunnel is 1,5mm steel when the sides are 1,5mm aluminium.

You can't probably go much higher than 5000Nm/deg if you plan on using the book chassis. Going higher than this would require welding additional tubing, which our racing series doesn't allow.

Analysing the frame made me realize that it was quite simple to make a stiff frame. I had it pretty much as stiff as it can get right from the beginning. What really amazed me how easily you can ruin the stiffness of the car, just removing one of the most critical panels (or making it non-structural by having it removable) can lower the torsional stiffness by 25%!

The colors show how much the frame twists, red being the highest. Same forces as in the previous pictures.

The colors show how much the frame twists, red being the highest. Same forces as in the previous pictures.The torsional stiffness is 4165Nm/deg, which is quite much more than the numbers by Ron Champion (1630-2030Nm/deg). The roll cage brings more stiffness, and the stiffness of the ready frame is usually 15-20% less than that of the calculated.

The frame is as it will be when we build the car, so all wall thicknesses for the tubes are 1,5mm. The floor, firewall and propshaft tunnel is 1,5mm steel when the sides are 1,5mm aluminium.

You can't probably go much higher than 5000Nm/deg if you plan on using the book chassis. Going higher than this would require welding additional tubing, which our racing series doesn't allow.

Analysing the frame made me realize that it was quite simple to make a stiff frame. I had it pretty much as stiff as it can get right from the beginning. What really amazed me how easily you can ruin the stiffness of the car, just removing one of the most critical panels (or making it non-structural by having it removable) can lower the torsional stiffness by 25%!

Friday, February 9, 2007

FEA addition

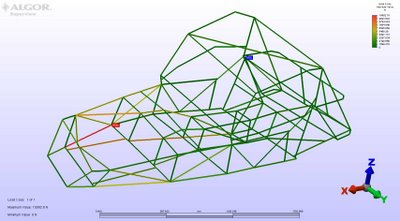

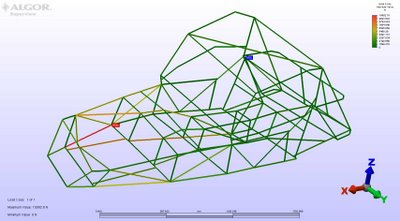

In the program the color scale being used is pink where there is maximum compression, and blue where there is maximum pull. But it's a bit difficult to get a clear picture of the forces involved because of the scaling. I just found a menu where you can change the colors to make it a bit easier to see the forces. Green shows the lowest forces in the tubes, when red is the highest.

The picture shows the most stressed tubes in the frame when it is being twisted. This picture isn't related to material thicknesses used in the model, it just shows how much force goes through each tube. As you can see the colors in the roll cage are nice and even, so not that much going on there.

The picture shows the most stressed tubes in the frame when it is being twisted. This picture isn't related to material thicknesses used in the model, it just shows how much force goes through each tube. As you can see the colors in the roll cage are nice and even, so not that much going on there.

The tubes that have to work the hardest are the R tube and the tubes around it on the right side of the engine bay. The triangulated structure seems to take quite a bit load off the left side. If only we would be allowed to have two R tubes. The loads in the prop shaft tunnel tubes should be sorted out once we get the panels added.

The picture shows the most stressed tubes in the frame when it is being twisted. This picture isn't related to material thicknesses used in the model, it just shows how much force goes through each tube. As you can see the colors in the roll cage are nice and even, so not that much going on there.

The picture shows the most stressed tubes in the frame when it is being twisted. This picture isn't related to material thicknesses used in the model, it just shows how much force goes through each tube. As you can see the colors in the roll cage are nice and even, so not that much going on there.The tubes that have to work the hardest are the R tube and the tubes around it on the right side of the engine bay. The triangulated structure seems to take quite a bit load off the left side. If only we would be allowed to have two R tubes. The loads in the prop shaft tunnel tubes should be sorted out once we get the panels added.

FEA, frame with roll cage

Modeling continues

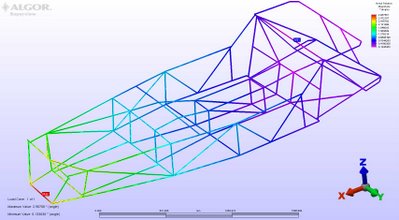

Now the frame twists 1,7 degrees with the same forces as in the previous picture. There is 70% more stiffness compared to without the roll cage. The diagonal in the roof contributes to 30% of the addition in stiffness. The color in the nose says that it twists much more evenly than before, and the roll cage distributes load even to the trunk area.

Now the frame twists 1,7 degrees with the same forces as in the previous picture. There is 70% more stiffness compared to without the roll cage. The diagonal in the roof contributes to 30% of the addition in stiffness. The color in the nose says that it twists much more evenly than before, and the roll cage distributes load even to the trunk area.

There's still a little more tweaking with the frame to get the forces to load more evenly. I also figured out how to add the panels, as I thought the mistake I made was very small...

Now the frame twists 1,7 degrees with the same forces as in the previous picture. There is 70% more stiffness compared to without the roll cage. The diagonal in the roof contributes to 30% of the addition in stiffness. The color in the nose says that it twists much more evenly than before, and the roll cage distributes load even to the trunk area.

Now the frame twists 1,7 degrees with the same forces as in the previous picture. There is 70% more stiffness compared to without the roll cage. The diagonal in the roof contributes to 30% of the addition in stiffness. The color in the nose says that it twists much more evenly than before, and the roll cage distributes load even to the trunk area.There's still a little more tweaking with the frame to get the forces to load more evenly. I also figured out how to add the panels, as I thought the mistake I made was very small...

Tuesday, February 6, 2007

3d model is ready for FEA

The wireframe feels ready. I already got to twist a simplified version in a FEA program.

The frame is supported from the upper rear damper mounting points, and it is twisted from the upper front damper mounting points.

The frame is supported from the upper rear damper mounting points, and it is twisted from the upper front damper mounting points.

I got a stiffness of 936Nm/deg, when Ron Champion says the ready frame should be 1630-2030Nm/deg. At this point adding panels seems a bit difficult, but hopefully it will get sorted quite easily.

The frame is supported from the upper rear damper mounting points, and it is twisted from the upper front damper mounting points.

The frame is supported from the upper rear damper mounting points, and it is twisted from the upper front damper mounting points.I got a stiffness of 936Nm/deg, when Ron Champion says the ready frame should be 1630-2030Nm/deg. At this point adding panels seems a bit difficult, but hopefully it will get sorted quite easily.

Monday, February 5, 2007

First car painted

The team's official photographer got himself so expensive equipment that he can't empty the camera, so I'll have to post some pictures taken with my own :-)

Henrik's car will be baby blue with carbon fenders.

The dashboard is still a work in progress, and the nosecone has a small fault on the other side. Might be that we will have to make a small bulge to the nose cone to fit the radiator. There is two manufacturers for these Renault Clio radiators, and seems like we bought the slightly bigger one.

Moottoritilan peltien sapluunat pitäis kans tehdä piakkoin.

The aluminium for the trunk was made from 1,5mm aluminium, and it required quite a bit of persuasion to get it into form.

Hopefully Henrik will post more pictures very soon!

-Mika

Henrik's car will be baby blue with carbon fenders.

The dashboard is still a work in progress, and the nosecone has a small fault on the other side. Might be that we will have to make a small bulge to the nose cone to fit the radiator. There is two manufacturers for these Renault Clio radiators, and seems like we bought the slightly bigger one.

Moottoritilan peltien sapluunat pitäis kans tehdä piakkoin.

The aluminium for the trunk was made from 1,5mm aluminium, and it required quite a bit of persuasion to get it into form.

Hopefully Henrik will post more pictures very soon!

-Mika

Subscribe to:

Posts (Atom)