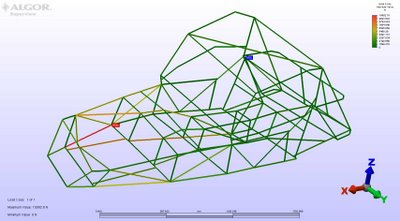

The picture shows the most stressed tubes in the frame when it is being twisted. This picture isn't related to material thicknesses used in the model, it just shows how much force goes through each tube. As you can see the colors in the roll cage are nice and even, so not that much going on there.

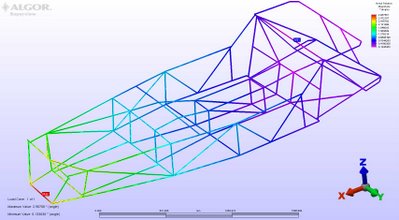

The picture shows the most stressed tubes in the frame when it is being twisted. This picture isn't related to material thicknesses used in the model, it just shows how much force goes through each tube. As you can see the colors in the roll cage are nice and even, so not that much going on there.The tubes that have to work the hardest are the R tube and the tubes around it on the right side of the engine bay. The triangulated structure seems to take quite a bit load off the left side. If only we would be allowed to have two R tubes. The loads in the prop shaft tunnel tubes should be sorted out once we get the panels added.

A picture of our jigtable, it is for both front a-arms.

A picture of our jigtable, it is for both front a-arms. We got the upper front a-arms sorted out too, they just need to be welded together. So the front end is looking quite good at the moment, all it need is to be welded together.

We got the upper front a-arms sorted out too, they just need to be welded together. So the front end is looking quite good at the moment, all it need is to be welded together.